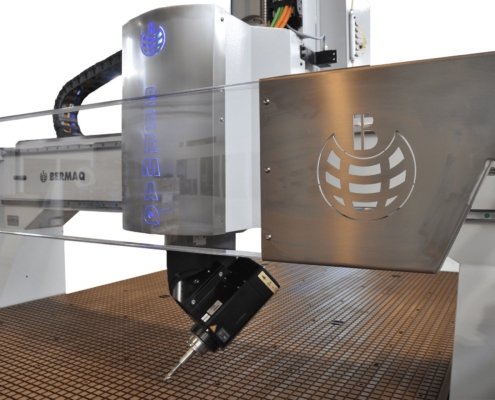

The CNC milling machine VISCOM 5X has been designed to meet the most demanding machining requirements. Its high productivity, versatility, and state-of-the-art technology allow it to work a wide range of non-ferrous materials (aluminum, wood, foam, resins, plastics, methacrylate, composite, etc.) and to achieve all kinds of shapes and finishes.

This 5-axis interpolated CNC router with optimized control is used in machining processes that require high precision and complexity.

Thanks to its high customization capacity and multi-purpose performance, the VISCOM 5X is perfect for all sectors (from the graphic arts sector to the aeronautics sector). It is a machine designed to successfully machine general industry projects. This model is also manufactured in 3 axes: VISCOM.

Video

Technical specifications

- Machine equipped with 5 controlled axes.

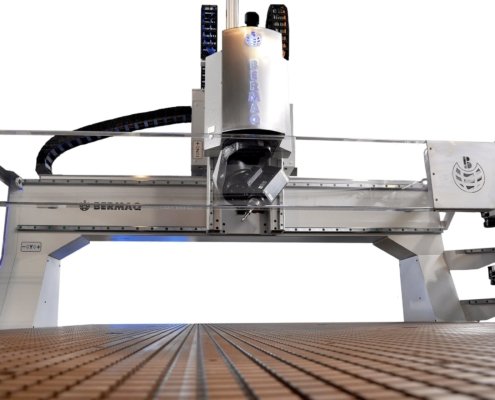

- Movable bridge structure.

- Movable control panel.

- Customizable working area:

- X: from 1.550 mm to 10.000 mm.

- Y: from 1.000 mm up to 3.000 mm.

- Z: from 500 mm.

- C: Infinite.

- A: Infinite.

- Milling head: HSK-F63 11kW, liquid cooling system.

- Nominal speed: 12.000 rpm.

- Maximum speed: 20.000 rpm.

- Workpiece vacuum clamping: phenolic resin grid table with 8 automatic and independent vacuum zones (configurable from the control panel and even from the machining program), and incorporates threaded metal inserts for clamping workpieces and tools. Also available with micro-perforated aluminum table.

- Vacuum pump of 290 m³/h or Super turbine of 1.000 m³/h of variable speed.

- Tooling tester.

- Automatic lubrication throughout the machine.

- Choice of CNC control: OSAI, SIEMENS or HEIDENHAIN.

- Tool change: double turret with 16 positions capacity located on the bridge. 10-tool linear tool change located on the bed (optional), offering a total of 26 positions.

- Speed of movement:

- X: 55 m/min

- Y: 55 m/min

- Z: 20 m/min

- C: 75º/sec.

- A: 75º/sec.

Applications

- Graphic arts sector: illuminated signs, advertising panels, elements for stands and engravings, etc.

- Industrial sector: household appliances, machining of composites, plastics, wood and aluminum, etc.

- Construction sector: Corian, aluminum profiles, PVC and Alucobond for facades, Solid Surface, etc.

- Decoration sector: trimming of screens, carpets, advertising objects and gifts, etc.

- Naval sector: manufacture of naval furniture and pontoons, manufacture of parts, etc.

- Aeronautical sector: manufacture of composites of different materials and aluminum parts.

- Railway sector: manufacture of aluminum profiles, car/carriage furniture cut-outs, etc.

- Automotive sector: manufacture of various molds for automobiles.

Optionals

- Retractable table tops

- Air conditioning

- 2 work areas

- Pneumatic plugs

- Air/liquid tool cooling (VIP4tools)

- Cold air tool cooling (VORTEX)

Description

The machining of materials with 5-axis machinery is an effective method for reducing the number of fixtures required to complete the entire workpiece and increasing precision when machining complex or multi-faceted parts.

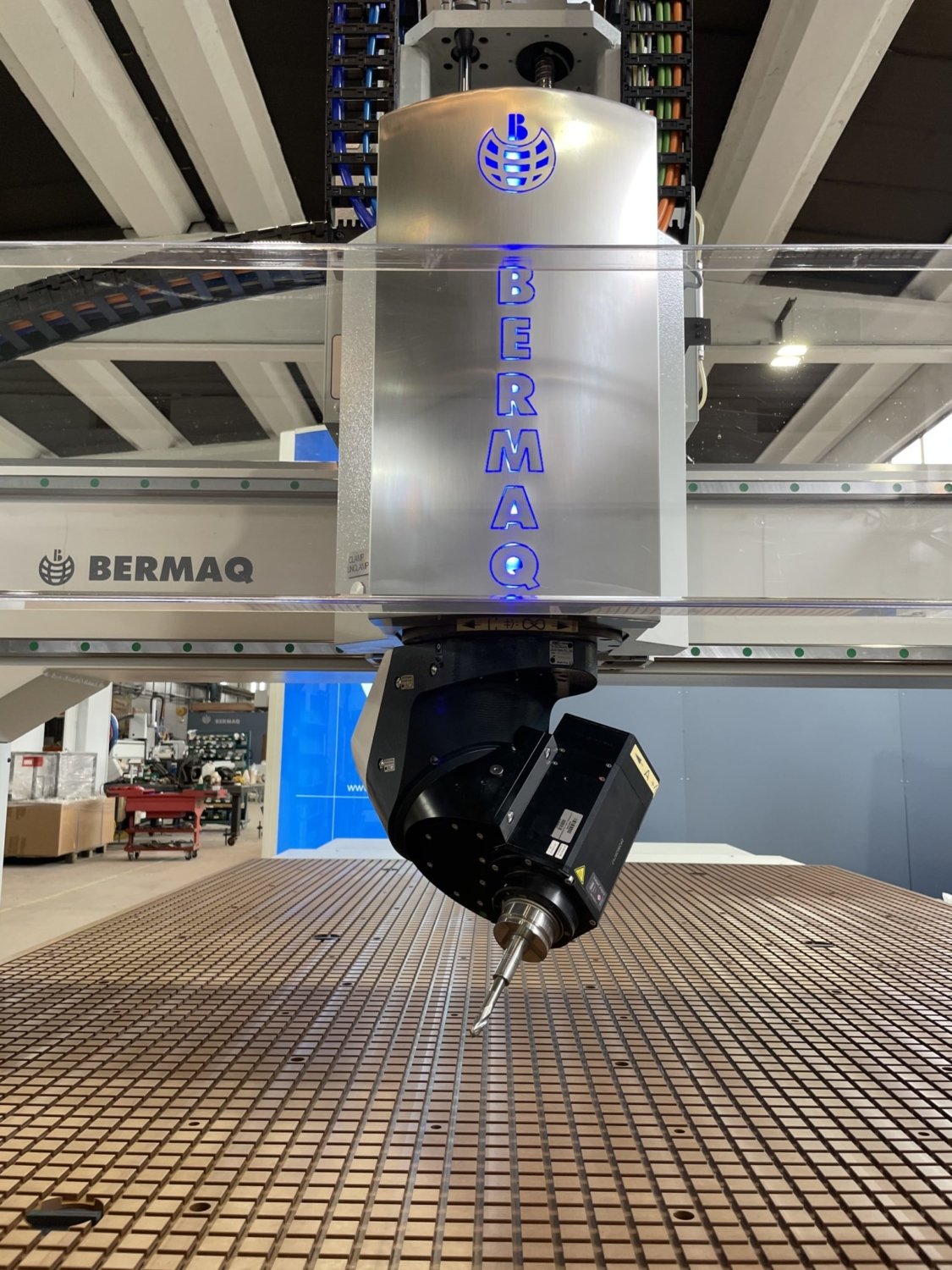

This industrial CNC milling machine designed and manufactured by BERMAQ® stands out for its robustness, versatility, and quality, offering a guarantee of unmatched productivity. It has an electro-welded and thermally stabilized steel bed and bridge for high stability and reliability.

Its compact and optimized design makes it a robust and modular CNC milling machine. Its structure allows easy customization of the machine with optimal solutions according to the production requirements of each customer. This model has a wide range of customized solutions to meet the needs of each project. At the same time, its solid structure guarantees greater resistance to continuous work and high machining requirements.

For the transmission in the X and Y axes, racks and pinions with helical ground teeth are used, as well as precision planetary gearboxes, to ensure maximum precision work.

Equipped in the Z-axis with a high load capacity spindle and preloaded nut with internal recirculating balls, it allows high precision machining and ensures a high-quality finish, as well as a very quiet operation.

The Z-axis travel with a bridge passage height of 500mm allows a variable machining volume. Being a highly customizable machine, it is possible to choose its features. Based on standard parameters, each BERMAQ VISCOM 5X CNC milling machine can be adapted to the needs of each customer (X: from 1,550 mm to 10,000 mm – Y: from 1,000 mm to 3,000 mm – Z: from 500 mm).

The Z-axis movement is assisted by pneumatic compensation to extend the service life. As for the C and A axes, their movements are infinite to improve machining times and finishes.

To ensure that the interpolation of all axes of the machine is perfect, we perform a precision kinematic calibration to ensure total synchrony of the machine and the movement of all axes.

(WATCH VIDEO) .

BERMAQ’s VISCOM 5X 5-axis CNC milling machine has an 11kW milling head in HSK-F63 and liquid cooling, tool tester for height calibration, phenolic resin vacuum table with 8 automatic and independent vacuum zones (configurable from the control panel and even from the machining program), and incorporates threaded metal inserts for clamping parts and fixtures.

It has a double revolver tool changer with a capacity of 16 tools located on the bridge, to which can be added a 10-tool linear tool changer located on the bed (optional), offering a total of 26 positions.

Thanks to the VISCOM 5X’s automatic centralized lubrication pump, the machine is virtually maintenance-free.

One of the most innovative features of the VISCOM 5X is that this CNC machine has the ability to work autonomously, and thanks to its remote control, it is possible to record and playback the entire process in streaming to follow it comfortably remotely from any place and device.

(WATCH VÍDEO) .

In summary, the 5X CNC milling machine is a numerical control machining center specialized in jobs that require both power and precision performance with high workloads. It is an industrial milling machine for a wide range of sectors and has features and functionalities focused on working comfort and machining perfection, in addition to being able to supervise all the work remotely. All this can be customized according to the customer’s needs.

Sectors