The hot-wire cutting machines 300C and 300C PLUS are perfectly suitable for the production of heat-insulated windows and doors. This new CNC pantograph has been developed specifically for cutting insulated EPS blocks and XPS components. The new trends in energy efficiency and the continuous orders of machines for cutting polystyrene for insulation of doors and windows have facilitated the creation of this new model.

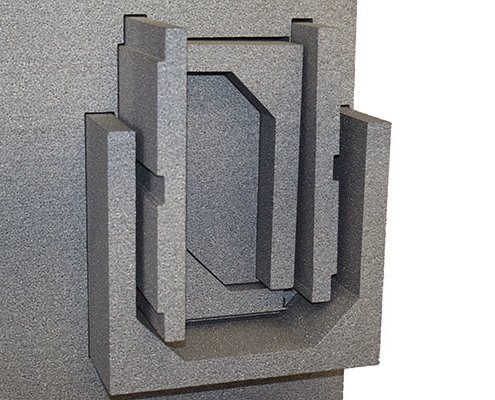

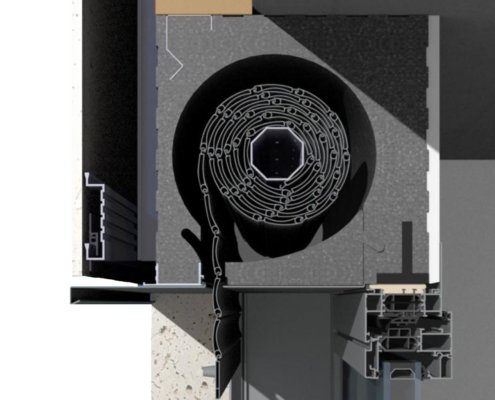

Expanded or extruded polystyrene is used to create the shutter box and thermal block components that guarantee excellent waterproofing. Today almost 90% of new buildings have doors and windows with thermal and acoustic insulation.

This is why the Italian brand Nettuno Sistemi has developed a polystyrene cutting machine specifically designed for the production of EPS and XPS parts for door and window insulation.

Video

Description

The attention for the construction of buildings and houses that comply with the Request for Energy Saving and Energy Efficiency, in recent years, has meant that all companies operating in windows and doors have adapted their production to this new requirement to ensure that buildings have adequate thermal and acoustic insulation.

The combination of the external insulation finishing system for facades (EIFS) with the new insulation systems for doors and windows has resulted in an effective reduction in heat loss due to the old window and door frame used in the past.

EPS and XPS are materials that are easily adaptable and customizable to different sizes, but above all they increase the acoustic and thermal insulation of the house, in accordance with current regulations and market demand. This is why Nettuno Sistemi has developed a foam cutting machine specifically designed for companies operating in the thermal insulation window and door sector: 300C (also available in the Plus version).

Perfect size

The cutting area of the 300C is perfectly suitable for the production requirements for the construction of insulated shutter boxes and thermal/acoustic insulation monoblocks for windows and doors.

Technology, efficiency and productivity

The 300C CNC hot wire cutter is equipped with the most advanced technological solutions, which ensure high efficiency and productivity.

Advanced software

Thanks to the Nettuno Sistemi software, the 300C is able to process multiple and complex cuts in the polystyrene block with the possibility of having a 3D preview of the result to be obtained.

Specifications

300C |

300C PLUS | |

|---|---|---|

| Cutting area mm | X = 1400 mm; Y = 1250mm | X = 1400 mm; Y = 1250mm |

| Number of Axes | 4 independent | 4 independent |

| Axes speed mm/min | 8.000 mm/min | 13.000 mm/min |

| Accurancy | +/- 0.05 | +/- 0.05 |

| Wire Lenght | 3.000 mm | 3.000 mm |

| Cutting Wire | Titanio | Titanio |

| Diameter Cutting Wire | 0,25 – 0,30- 0,40 mm | 0,25 – 0,30- 0,40 mm |

| Table Top | Composit panels Fire Resistant | Technical wooden panels Fire Resistant |

| Transmission | Recirculating ball bearing guides | Recirculating ball bearing guides |

| Estructura | Aluminum and steel | Aluminum and steel |

| Motors | Stepper | Stepper closed loop |

| Wire Tensionin | By springs | Pc controlled tensioning system |

| Operator interface | Nettuno Docker Cam | Nettuno Docker Cam |

| Workstation | Yes | Yes |

| Wireless remote control | Included | Included |

| Vertical Turntable | Optional | Optional |

| Shapeable Wire | Optional | Optional |

| Horizontal Lathe | Optional | Optional |

| Clevel | Optional | Optional |

| Power supply | 230V 50/60Hz 1kW | 230V 50/60Hz 1kW |

Aplications

The CNC hot wire cutting machines 300C and 300C PLUS allow you to produce with ease and precision:

- Shutter boxes for windows.

- EPS / XPS sides for windows.

- Components made of expanded/extruded polystyrene to insulate the entire structure of the windows/doors.

- Insulating monoblocks for windows ready to be installed on-site.

Obviously, being a versatile hot wire cutting machine equipped with 4 independent axes, the polystyrene elements for window/door insulation can be produced in different sizes. It is possible to customize them so that they can be completely adapted to the needs of new buildings or existing buildings undergoing restoration.

The 300C hot wire cutter, thanks to its state-of-the-art software, can also be used to cut other types of shapes and elements related to the construction sector: polystyrene formwork, EPS / XPS prefabricated, columns/pillars, cornices, capitals, decorative elements for facades, exterior, and interior design.

Sectors